Background

A satellite dish is a parabolic television antenna that receives signals from communication satellites in orbit around the earth. Its sole function is to provide the television viewer with a wider variety of channels.

The first communications satellite— Echo I —was launched by the United States in 1960, transmitting telephone signals. In 1961 Relay began transmitting television signals, and in the same year Syncom established itself as the first geosynchronous satellite capable of transmitting signals to one particular section of the earth’s surface continuously.

The rapid advances in communication satellite technology were not simultaneously matched by advances in satellite dish use and technology. Television broadcasting began with individual stations that could only serve a limited area. Television networks had to provide their affiliate stations with recordings of programs if they wished to provide nationwide service. Satellite television was not widely available until the 1970s, when cable television stations equipped with satellite dishes received signals that were then sent to subscribers by coaxial cable. By 1976, there were 130 satellite dishes owned by cable companies, and by 1980, every cable television station had at least one satellite dish.

About that time personal satellite dish earth stations were selling for approximately $35,000 per unit. Taylor Howard, an employee at Stanford University who was well-versed in the usefulness of satellites as relayers of data, is credited with designing the first satellite dish for personal use. Howard’s dish, which was placed into operation on September 14, 1976, was made of aluminum mesh and was about 16 feet (5 meters) wide. By 1980,5,000 satellite dishes had been purchased for home use. In 1984 alone 500,000 were installed. Recent reports state that there are 3.7 million owners of home satellite dishes worldwide, and the number will continue to grow.

A typical commercial satellite dish of the 1970s was made of heavy fiberglass, and the dish itself, at its smallest size, had a diameter of about ten feet (three meters). Since then, satellite dish design has shifted toward light-weight, aluminum mesh dishes (similar to Howard’s homemade dish), some of which are inexpensive and small (three feet, or one meter, in diameter is typical), with many sections (petals) that can be easily assembled. England, Japan, and Germany, have led the way with direct broadcast TV, which sends signals directly to the viewer’s dish, but the United States has yet to do so. This trend would yield smaller, more affordable satellite dishes and regulated satellite programming.

Raw Materials

The basic satellite dish consists of the following materials:

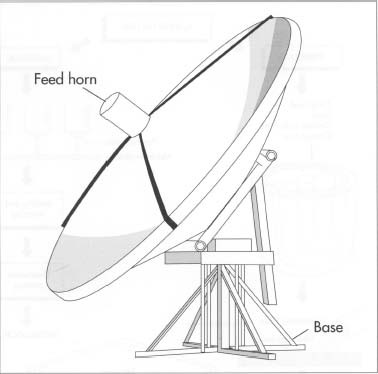

- A parabolic reflector made of fiberglass or metal, usually aluminum, with a protruding steel feed horn and amplifier in its middle.

- A steel actuator that enables the dish to receive signals from more than one satellite.

- A metal (usually aluminum) shroud measuring about 6 to 18 inches (15 to 45 centimeters) in height. It is installed on the dish’s circumference perpendicularly to reduce side interference.

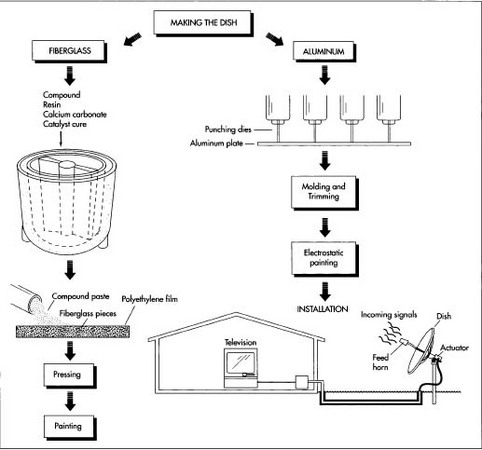

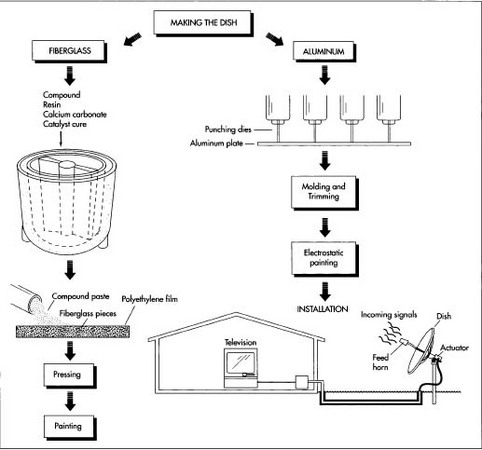

The manufacture of fiberglass dishes involves first preparing a compound paste that contains resin and calcium carbonate and pouring it onto a polyethylene film with fiberglass bits embedded in it. The material is then pressed into shape. In contrast, aluminum dishes are perforated with punching dies and molded into shape.

- Cables, most likely made from vinyl tubing and copper wiring.

The Manufacturing

Process

- 1 To make fiberglass suitable for dish manufacture, a sheet molding compound mixture that includes reflective metallic material and ultraviolet scattering compositions is mixed with resin, calcium carbonate, and a catalyst cure. This mixture forms a paste that is poured onto a sheet of polyethylene film that has fiberglass added in chopped form. The result is a sheet layered with the compound paste, fiberglass, and the polyethylene film.

- 2 This sheet is then pressed at 89 degrees Fahrenheit (30 degrees Celsius) to mature. To shape the sheet into the desired parabolic shape, it is pressed at high pressure (of 1,400-2,200 metric tons). The dish is then trimmed, cooled, and painted. After the paint has dried, the dish is packed for shipment in sturdy boxes.

- 3 For metallic dishes, the common metal of choice is aluminum. This type of dish can

Although some current home satellite dishes are very small—only about 3 feet in diameter—manufacturers have begun to introduce even smaller dishes that have a diameter of only 18 inches and can fit on a window sill or a porch.

be assembled in sections called petals, or all at once. An aluminum plate is perforated with a punching die, creating tiny holes. The size of these holes are contingent on the manufacturer’s preference. Larger holes mean greater loss of the signal, so fairly small holes are selected. Another factor in the selection of hole size is the power of the broadcasting satellite. Newer, more powerful satellites require a hole size that is approximately half that required for older, less powerful satellites. The newly perforated aluminum plate is then heated, stretched over a mold, cooled, and trimmed. A paint powder coating for protection is then applied using an electrostatic charge, in which the paint is given an opposite electrical charge from the plate. The dish or petal is then heated to melt the powder and seal the paint on. The petals are usually sealed together with ribs in the factory.

- 4 Mesh petals are made from aluminum that is extruded—forced into a die of the proper shape. They are usually joined together on site by sliding them into aluminum ribs that attach to the hub and then securing them with metal pins.

Installation

- 5 All dishes, when complete, will have the necessary equipment (the feed horn, the amplifier, etc.) installed in the factory. When the dish has been set up at the local dealer, it is transported to the site location on a open trailer. Satellite dishes can be installed either by professionals or by the purchaser, with assistance from the retailer if necessary. The method selected depends upon the size of the dish and the mechanical expertise of the purchaser.

- 6 An installation site reasonably clear of obstructions not more than 246 feet (75 meters) from the house is selected. Site selection is also contingent on local building codes and the possibility of microwave interference from radio and television towers in the vicinity. Once a site is selected, the base must be installed first. The base of most satellite dishes consists of a concrete foundation that extends below the frost line. A clayey soil is excellent, while sandy or rocky soil requires more concrete. A base tube filled with concrete is then set into the concrete foundation.

Some satellite dishes require a slab mount installation, a method considered to be more stable than typical base construction. In some cases, slab mount installation is necessary since the site selected for the placement of the satellite dish is unstable. The slab is generally 1.6 feet (.5 meter) square and 3.2 feet (1 meter) deep. Soil is excavated to the proper depth and the concrete is poured. A triangular steel mount fixture is then embedded into the concrete.

- 7 Next, the pedestal is attached to either the base tube or the triangular steel mount fixture. The elevation arm is then attached to the pedestal.

Alignment

- 8 The mounted satellite dish must be aligned in order to point toward the satellite. The angle at which the dish is eventually situated will vary according to which satellite is selected and at what latitude the dish is located. Coaxial cables connect the satellite to the receiver that is located in the house near the television. A trench must be dug for these cables, which are placed into a pipe before being buried.

Quality Control

Satellite dishes for consumer use are not usually required to undergo rigorous tests with set standards, but some parameters are generally met. For example, so that the microwaves are received properly, the surface of the dish should be as smooth as possible and its parabolic shape should be exact. It must also be composed at least partially of metal, otherwise the microwaves will not reflect. If the dish is either mesh or perforated aluminum, the holes must be relatively tiny to minimize loss. Dish size is important; it should match that appropriate to the latitude. The mount should be sturdy, and the dish aligned properly for maximum reception.

Members and joints are tested and compared to the American Steel Construction Institute or the American Aluminum Association methods rules, whichever apply. The satellite dish should be built to withstand high winds, snow, ice, rain, and extreme temperatures.

After the dish is installed, the owner is generally responsible for cleaning it twice a year, more if necessary, tightening and lubricating all bolts once a year, and trimming obstructive weeds and trees from around it. In rare occasions, the owner must adjust the alignment to correct bad reception.

The Future

Satellite dishes will become ubiquitous in upcoming years. More communication satellites will certainly be launched, and the growth explosion in individual satellite dish ownership will continue. One factor that should affect home satellite dish ownership in the near future is the switchover to more powerful satellites that will transmit signals in the K band (12 GHz). Because most of the present satellite dishes accept signals in the C band (3.7 to 4.2 GHz), owners of C band satellite dishes will have to convert them to K band. Researchers and designers are contemplating even smaller dishes that could be placed on a rooftop or outside a window and still function as well as the larger satellite dishes of today.

Some experts see the growth of satellite television as a revolution that is less concerned with crystal clear images of old sitcoms than with the possibilities of two-way communication that universal dish ownership would promote. Satellite television will be used to pay bills, shop, and participate in game shows. It can also be used to communicate over long distances, perhaps to play interactive video games with someone halfway across the continent. Some visionaries see the revolution as the return of one-on-one communication like that of a town meeting. In any case, it is almost certain that satellite television will continue to proliferate in upcoming years.

Manufacturers will continue to make smaller and less costly satellite dishes. Recently, for instance, 18-inch (45.7-centimeter) diameter dishes have been introduced into the market in Japan, Europe, and the United States. These dishes are small enough to fit on a windowsill or a porch railing. Manufacturers are also working on producing a flat-plate dish for satellite signal reception.

Where To Learn More

Books

Baylin, Frank, and Amy Toner. Satellites Today. ConSol Network, Inc., 1984.

Clifford, Martin. The Complete Guide to Satellite TV. Tab Books, 1984.

Easton, Anthony T. The Home Satellite TV Book. Wideview Books, 1982.

Prentiss, Stan. Satellite Communications. Tab Books, 1987.

Sutphin, S. E. Understanding Satellite Television Reception. Prentice-Hall, 1986.

Traister, John E. Guide to Satellite Television Installation. Prentice-Hall, 1987.

Traister, Robert J. Build a Personal Earth Station for Worldwide Satellite TV Reception. Tab Books, 1985.

Periodicals

Booth, Stephen A. “Signals from Space,” Popular Mechanics. April, 1992, p. 60.

Elrich, David. “Satellite TV: It’s Worth a Closer Look,” Home Mechanix. September, 1990, p. 78.

— Rose Secrest