Published May 30, 2019

One in an occasional series

Nearly 50 years have passed since Neil Armstrong and Buzz Aldrin became the first humans to walk on the moon. The July 20, 1969, moon landing changed the world and forever changed Houston. Our “Mission Moon” project will explore how the country came together to fulfill President John F. Kennedy’s goal of reaching the lunar surface by 1970, NASA’s bold missions – and crippling tragedies – since that historic day, the future of space exploration and the fate of Houston as America’s “Space City.”

Read our entire series here.

The interns received a 3D printer and the Apollo 13 scenario: An explosion damaged part of your spacecraft, and you’re taking refuge in the lunar lander where air is becoming increasingly toxic. Square canisters can remove the carbon dioxide, but they must fit into the lunar lander’s round openings.

This 1970 life-or-death scenario was solved with plastic bags, cardboard, duct tape and a sock. But with a printer and thermoplastic feedstock, the interns at the commercial space company Made In Space created a more precise converter for the carbon dioxide filter in less than one hour.

Made In Space, headquartered in Jacksonville, Fla., sees 3D printers as a tool for making replacement parts and preventing mishaps deep in space from becoming dire situations. Just think about how comfortable Matt Damon, stranded on Mars as Mark Watney in “The Martian,” could have been with a 3D printer to repair his space habitat after an airlock explosion.

This undated photo provided by Made In Space shows a 3D Printer during testing in the Microgravity Science Glovebox (MSG) Engineering Unit at Marshall Space Flight Center. NASA sent a 3D printer to the International Space Station in hopes that astronauts will be able to one day fix their spacecraft by cranking out spare parts on the spot. (Associated Press)

“We joke that ‘The Martian’ would have been a much more boring movie,” said Justin Kugler, a vice president at Made In Space.

Fifty years after the first men walked on the moon, a new space race is underway, this one for a piece of what Wall Street analysts say could become a $1 trillion global space market. Around the world, companies such as Made In Space are launching — often literally — new products and services, building satellites to provide broadband internet, spaceships to take tourists on zero-gravity rendezvous, and mining equipment to extract minerals from asteroids.

On HoustonChronicle.com: Elon Musk injects ‘X’ factor into space quest with bold vision, mixed track record

The commercial space transition has gained momentum with assistance from deep-pocketed space enthusiasts, increasingly sophisticated yet compact technologies, and new government policies that position NASA to become one of many customers rather than the sole driver of the industry. The idea is to leave routine space activities, such as taking people and cargo to the International Space Station, to commercial companies while NASA musters resources for the most ambitious projects, such as putting humans on Mars.

-

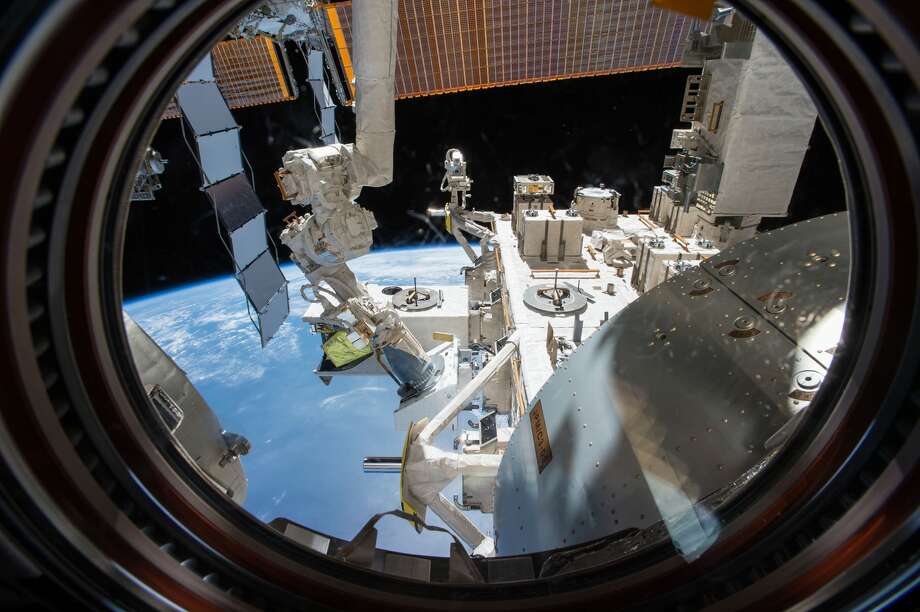

The NanoRacks External Platform (NREP) being installed outside the space station on the Japanese Experiment Module Exposed Facility. The NREP provides power and data to science payloads for a six-month mission outside the space station, then the experiments are returned inside the space station and then back to Earth in a SpaceX Dragon capsule.

The NanoRacks External Platform (NREP) being installed outside the space station on the Japanese Experiment Module Exposed Facility. The NREP provides power and data to science payloads for a six-month mission

… morePhoto: Courtesy NanoRacks

Photo: Courtesy NanoRacks

Image 1 of / 19

Image 1 of 19

The NanoRacks External Platform (NREP) being installed outside the space station on the Japanese Experiment Module Exposed Facility. The NREP provides power and data to science payloads for a six-month mission outside the space station, then the experiments are returned inside the space station and then back to Earth in a SpaceX Dragon capsule.

The NanoRacks External Platform (NREP) being installed outside the space station on the Japanese Experiment Module Exposed Facility. The NREP provides power and data to science payloads for a six-month mission

… morePhoto: Courtesy NanoRacks

In new space race, companies jostle for $1 trillion market

1 / 19

Back to Gallery

NASA has provided funding and technical expertise to SpaceX, the company founded by visionary billionaire Elon Musk, and Orbital ATK, an aerospace and defense company recently acquired by defense contractor Northrop Grumman, to develop vehicles that carry cargo to the space station. It’s also working with SpaceX and the Chicago aerospace company Boeing for vehicles to transport astronauts.

But private rocket companies are hungry for more. Musk talks about colonizing Mars. Amazon.com founder Jeff Bezos, who started the space company Blue Origin, imagines people living in giant cylinder colonies that float in space. The British magnate Richard Branson, whose Virgin Group includes the space flight company Virgin Galactic, is eyeing suborbital flights for tourists who can pony up the six-figure price of a ticket.

Such ambition generates excitement for commercial space, but futuristic projects also have suffered from delays and overly optimistic time frames. The real money in space, now and for the immediate future, comes from satellites. Satellites generated 77 percent of the $360 billion in global space revenues in 2018, according to analytics and engineering firm Bryce Space and Technology.

In this Oct. 17, 2011 photo a crowd gathers outside Spaceport America for a dedication ceremony as Virgin Galactic’s custom-built jet aircraft WhiteKnightTwo and its spacecraft SpaceShipTwo sit on the tarmac near Upham, N.M. British billionaire Richard Branson is taking another concrete step toward offering rides into the close reaches of space for paying passengers. Branson announced Friday, May 10, 2019, that Virgin Galactic will immediately begin shifting operations from California to a spaceport and specialized runway in the New Mexico desert in final preparations for commercial flights. He says Virgin Galactic’s development and testing program has advanced enough to make the move, which will continue through the summer. (Associated Press)

The rise of satellites

Russia launched the first man-made satellite, Sputnik 1, in 1957. Seven years later, the NASA-funded Syncom 3, an experimental communications satellite, beamed a live TV broadcast of the Tokyo Olympic Games’ opening ceremonies. It was the first time Americans watched an overseas sporting event in real time, having previously waited for tapes to be shipped to the United States.

The first commercial communications satellite was launched in 1965. These bus-sized satellites dominated the sector for decades.

Smaller satellites were launched around 2000, flying orbits closer to Earth. In the past 10 years, even smaller satellites known as cubesats, which start at just 4 inches wide by 4 inches long by 4 inches high, have been placed into orbits several hundred miles above Earth.

Cubesats can be launched at relatively low cost and capture images on Earth to provide information to people who can use it. In agriculture, for instance, the satellites can help monitor soil health and predict crop yields. Large retailers like the vantage point of space for counting cars in their parking lots.

On HoustonChronicle.com: Houston company solving the next problem of deep space travel: How to post to Instagram

“This revolution in putting more and more capability into a very small package has also changed the face of space exploration,” said Scott Hubbard, adjunct professor in Stanford University’s Department of Aeronautics and Astronautics and former director of NASA’s Ames Research Center. “Suddenly almost anybody can get a payload that can do something useful.”

An idea gaining prominence is using desk-sized satellites to provide broadband internet. Organizations are developing constellations of satellites to bring reliable internet service across the planet. The London company OneWeb, which has raised $3.4 billion, plans to launch about 650 satellites some 750 miles above Earth that would relay internet signals to remote areas of the world cut off from the digital revolution.

“There is no question, these are exciting times in the satellite industry,” said Tom Stroup, president of the Satellite Industry Association trade group.

Abe Rademacher, NASA BioSentinel mechanical lead, wires the engineering development unit of the Biosentinel cube satellite which will launch on the SLS EM-1, at the NASA Ames complex at Moffett Field, California, Thursday, June 8, 2017. (Thor Swift/For the San Francisco Chronicle)

Following the opportunities

More than 2,100 operational satellites orbit the Earth, prompting other commercial space opportunities. SpaceLogistics, a Dulles, Va. subsidiary of Northrop Grumman, is developing vehicles to keep satellites in orbit longer.

Large communications satellites, located roughly 22,000 miles above Earth, typically have enough fuel to hold their orbits for 15 years. When they run out of fuel, it costs $150 million to $300 million to build and launch a replacement satellite.

So SpaceLogistics created a jetpack-like spacecraft to dock with the satellite and essentially provide the fuel to maintain orbit, sort of like sending up a gas tank. The first Mission Extension Vehicle is expected to launch this summer and rendezvous with its satellite in December or January, said Joe Anderson, vice president of business development and operations.

On HoustonChronicle.com: NanoRacks project could be a giant leap

The Webster company NanoRacks is building the International Space Station’s first commercial airlock, an airtight enclosure that opens to space and allows NanoRacks to deploy satellites. Currently, satellites are deployed from an airlock in the Japanese Experiment Module of the space station, but the airlock can’t keep up with demand. The larger NanoRacks airlock would be able to accommodate five times more volume.

Deploying satellites from the space station is a gentler alternative to launching them from a rocket. NanoRacks CEO Jeffrey Manber said satellites destined for the space station ride inside a rocket’s pressurized cargo, which allows for more delicate components.

NanoRacks, founded 10 years ago, started by helping universities get research projects aboard the International Space Station to examine, for example, how microgravity affects bacteria mutations or materials’ composition. Now, it’s building complex components such as the airlock and participating in NASA studies on repurposing spent rocket stages into space hotels, research labs or satellite deployment platforms.

Is commercial space sustainable?

Manber recognizes that his business wouldn’t be possible without NASA subsidies. NanoRacks, for example, doesn’t pay the cost of launching research projects into space, and it doesn’t pay rent on the space station. Without this support, it would have to charge its university and other customers much more.

“The government has always subsidized emerging marketplaces,” Manber said, citing aviation, railroads and automobiles as examples. “Right now, if you took away that subsidization I’d lose a lot of my business.”

David Alexander, director of the Rice University Space Institute, a space exploration research center, said commercial space companies will first need to find customers willing to commit to buying their goods and services.

For example, companies that might mine ice deposits at the moon’s south pole — selling the water or splitting it into hydrogen and oxygen for rocket fuel — would need to secure contracts for the water, hydrogen and oxygen they produce, probably from NASA or other government agencies, before starting operations. Then they could add other customers.

“Commercial really means being able to make money,” he said, “so there’s a lot of discussion on how that will really work.”

A few example of the types of parts that can be made with a 3D printer in space are displayed at Made In Space on February 19, 2016, in Mountain View, California. (Michael Macon/San Francisco Chronicle)

Made In Space

Made In Space, the in-space manufacturing company, sees opportunity in making products without the effects of gravity. Its first project is creating better fiber optic cables. A substance known as ZBLAN is touted as a fiber optic that could transmit more data, but its potential has been stymied by gravity.

On HoustonChronicle.com: San Jacinto College takes step to open aerospace training center at Houston Spaceport

ZBLAN is made by heating a big rod of glass. When it gets to a consistency of taffy, the fiber is pulled onto a spool. On Earth, however, gravity causes small crystals to form, which limits the data-carrying light that can be sent down the cable.

Government experiments using parabolic flights, which fly giant arcs to create weightlessness, have shown that ZBLAN could be improved in microgravity. So, Made In Space has placed a ZBLAN experiment on the space station, said Kugler, the company’s vice president of advanced programs and concepts. If space manufacturing reaches a commercial scale, each kilogram of ZBLAN would be worth more than the cost of launching it to and from space.

“There’s a lot of growth opportunity for that once we get those early customers established,” Kugler said, “and show really what you can do with new materials made in microgravity.”

A rendering of satellite broadband coverage that could be provided by OneWeb’s proposed network of hundreds of satellites. (OneWeb via Los Angeles Times)

Andrea Leinfelder is the aviation and business enterprise reporter for the Houston Chronicle. Follow her on Twitter @andrearumbaugh or reach her by email at andrea.leinfelder@chron.com.

Design by Jordan Rubio and Jasmine Goldband

***